How I Made DeWit Tools By Hand

What if you could go to a blacksmith and forge garden tools by hand? Order up a tool designed to your specifications and make it yourself? Guess what? I DID THAT! ::jumping up and down with excitement::

Why I Went to the Dewit Tools Factory in the Netherlands

I traveled to the Netherlands to visit the Floriade and lecture. Sietse DeWit, CEO from Dewit Tools, invited me to his blacksmithing factory in Kornhorn, Netherlands. I learned what it is like to forge a garden tool for my own garden.

One of my garden trowel suggestions is to fix an issue I have. The soil spills out of the trowel as I plant my containers. My idea for a new trowel design was to build a rounded trowel – almost a scoop. I wanted it to have a sharp side for cutting the plastic bags of potting soil open and a sharpened bottom edge to cut old soil out of containers (see photo below). The DeWit’s loved the idea and I was able to work in the factory with the team to develop the prototype tool.

CLICK HERE to purchase an awesome Dewit handtool bundle of magnificence 3-Tool Bundle with Holder

How to Forge a Garden Trowel

Each step in the forging process involved such attention to detail. It took us four hours to build the prototype from beginning to end. These tools are special. They are an investment in the DeWit family. This post shares my experience of the process for making this special tool. Watch the video to see what it was like to be there.

How to Build a Prototype Garden Trowel at the DeWit Tools Factory

Building a prototype trowel starts with designing the tool on the computer. Above you see Derk Klaus Dewit designing with me and his uncle, Derk Dewit, supervising (yes, there are two Derk’s).

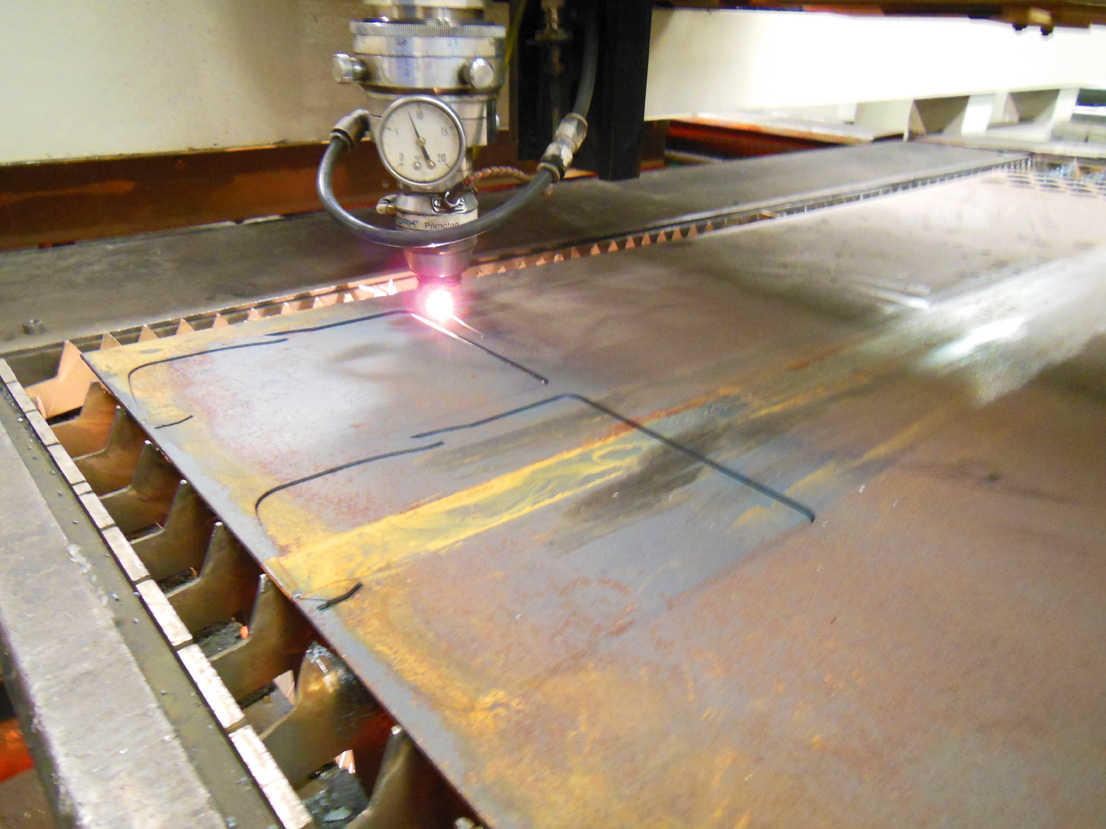

Designing the tool starts at the computer. A machine cuts the design from heavy metal into the scoop trowel shapes (below). The trowel is flat at this stage.

Welding the Handles On a Garden Trowel

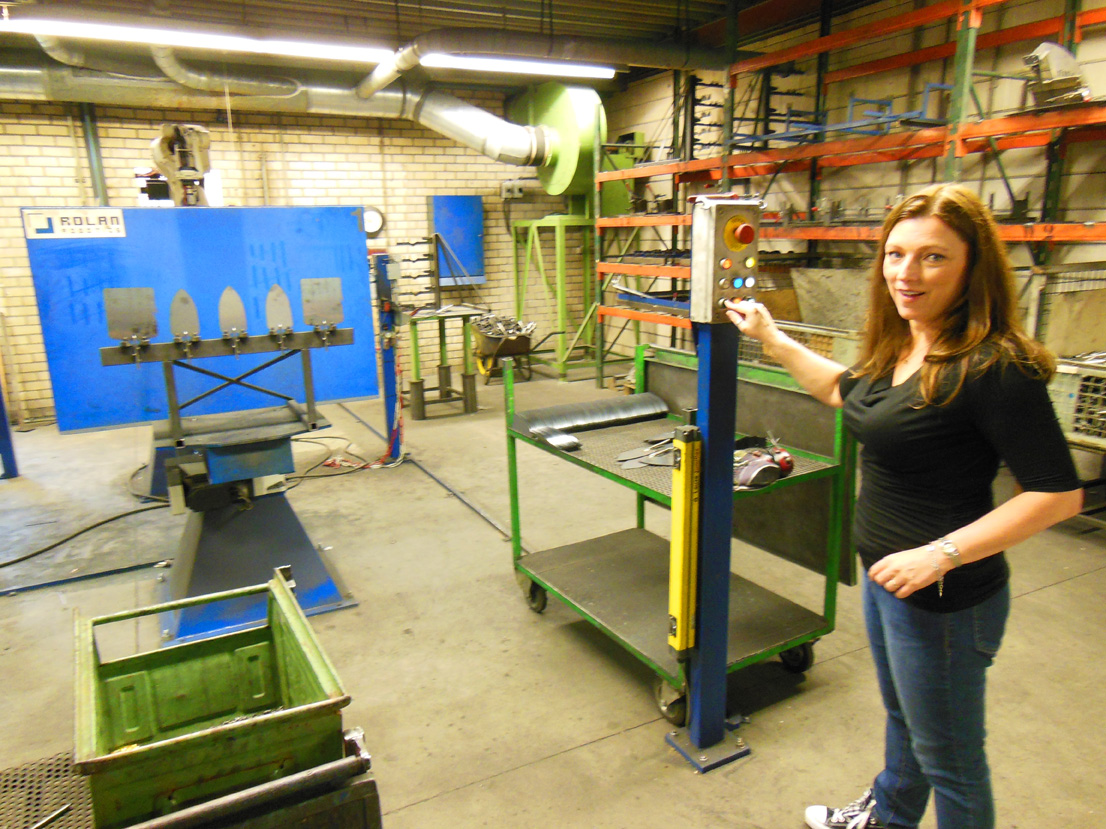

Above I am pushing a button for a giant welding machine to weld the flat metal trowel pieces to the metal handle. Yes. I am happy. This is fun!!

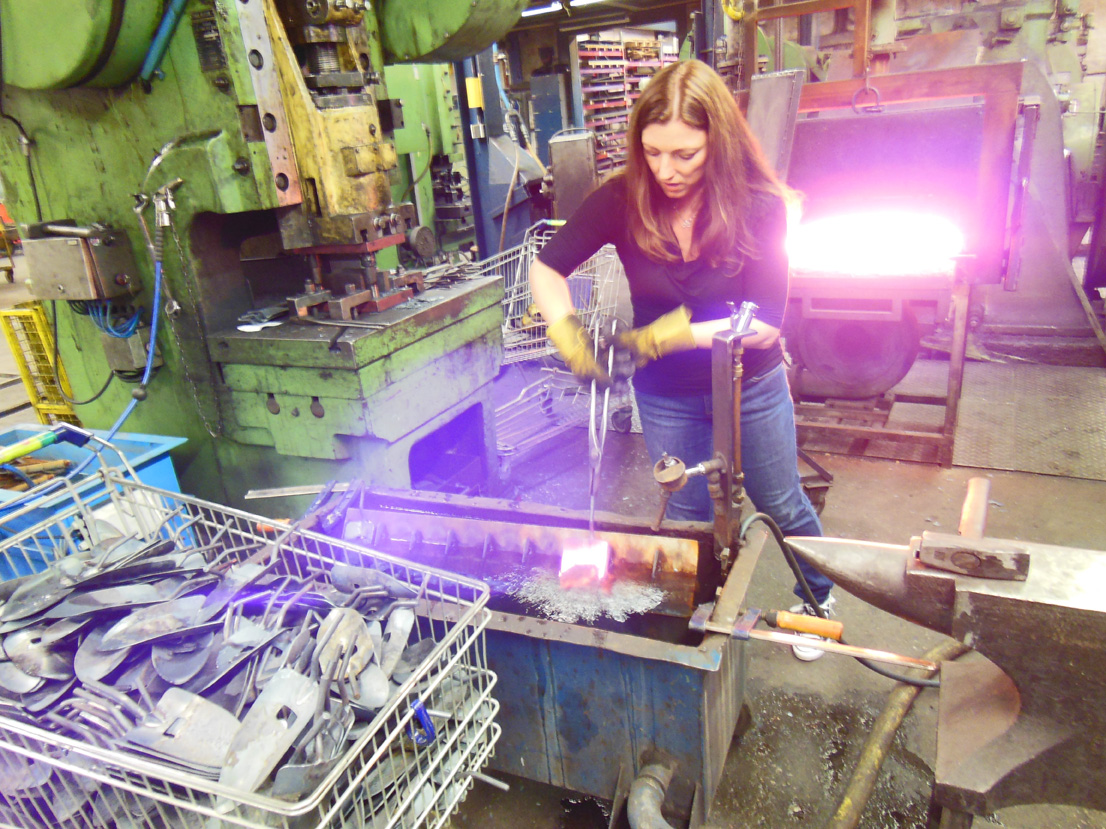

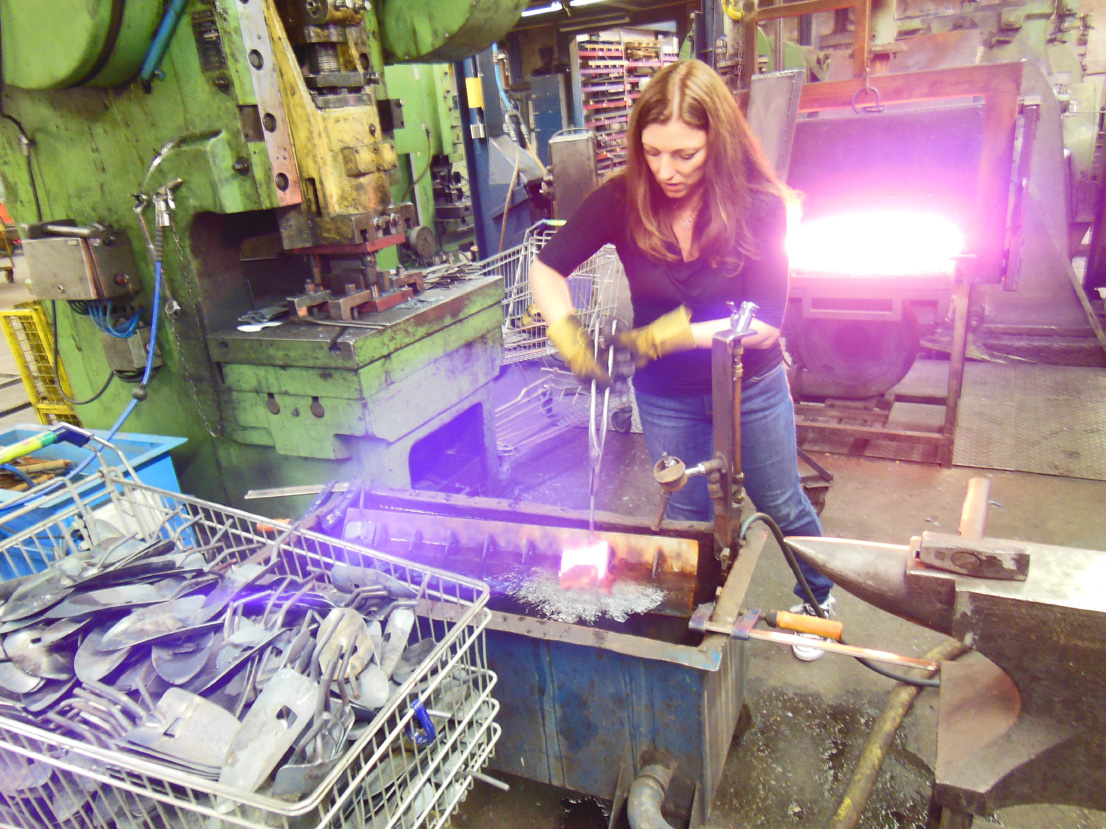

Next, the trowels have to go into a super hot blacksmithing forge. This forge is extremely hot. Within three feet of the forge it is super hot. It feels like all the power of the sun is on your face. Watch out eyebrows! I have immense respect for the workers who have to stand at the forge all day long. It saps your strength and would be a difficult job.

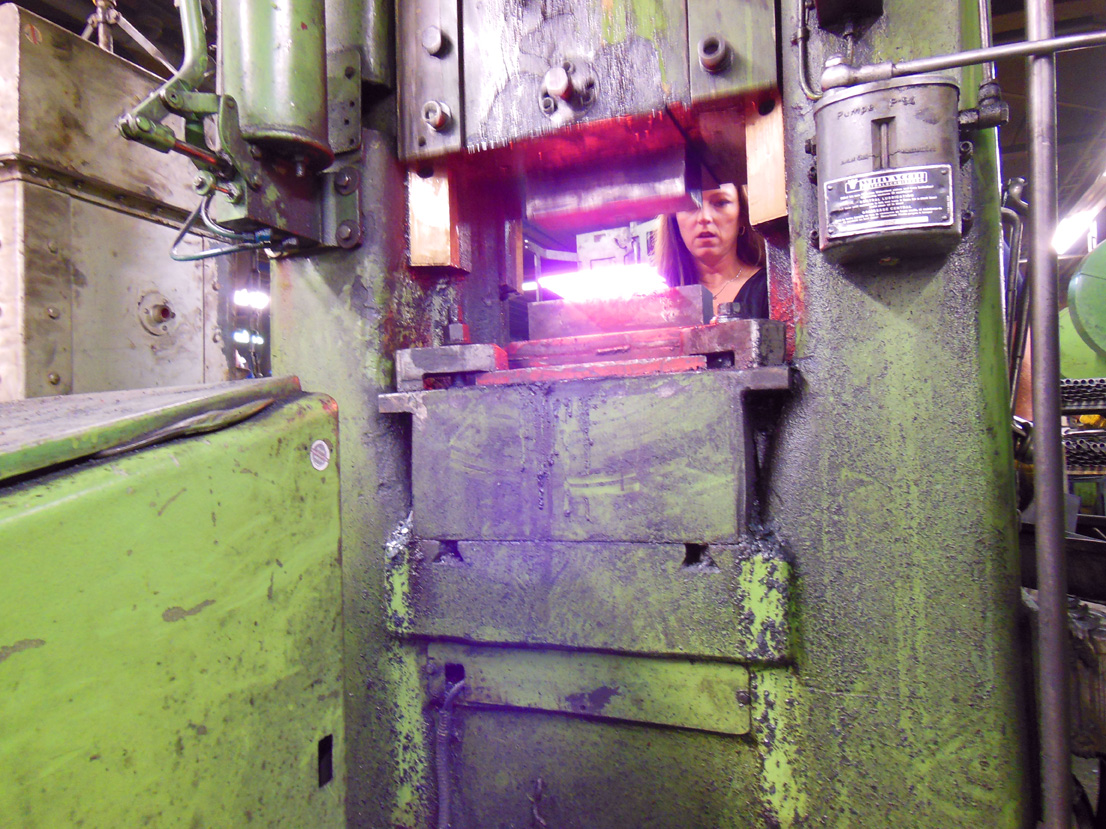

Forging a Seam on a Heated Metal Piece

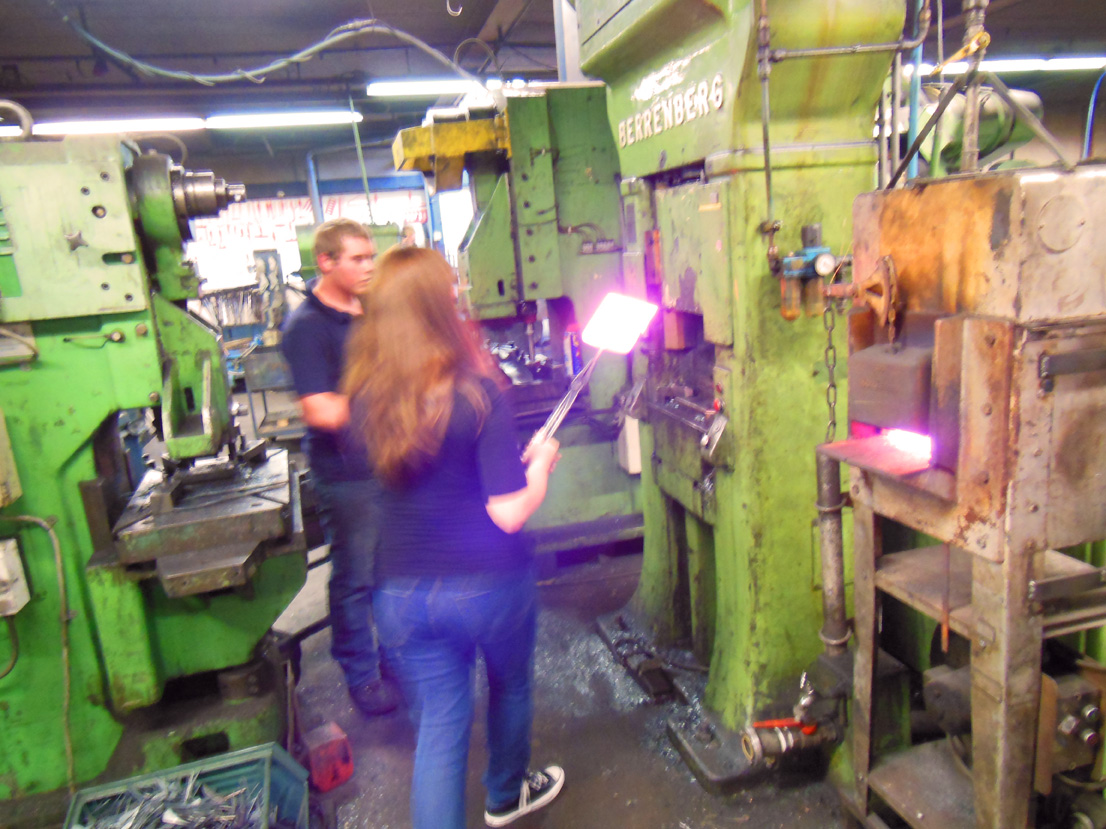

You see a series of two photos above which show me taking the heated flat trowel piece, placing it in a giant smashing machine (that’s a technical term) and smashing the seam together in a reinforcement process.

After reinforcing, we take the metal and forge it into a curve shape. The red-hot blade is insert into a special mold. The mold squishes it into shape. We cool the hot form in water. Below you see me removing the tool and cooling it in the water.

Forge Garden Tools by Hand Back and Forth as a Process

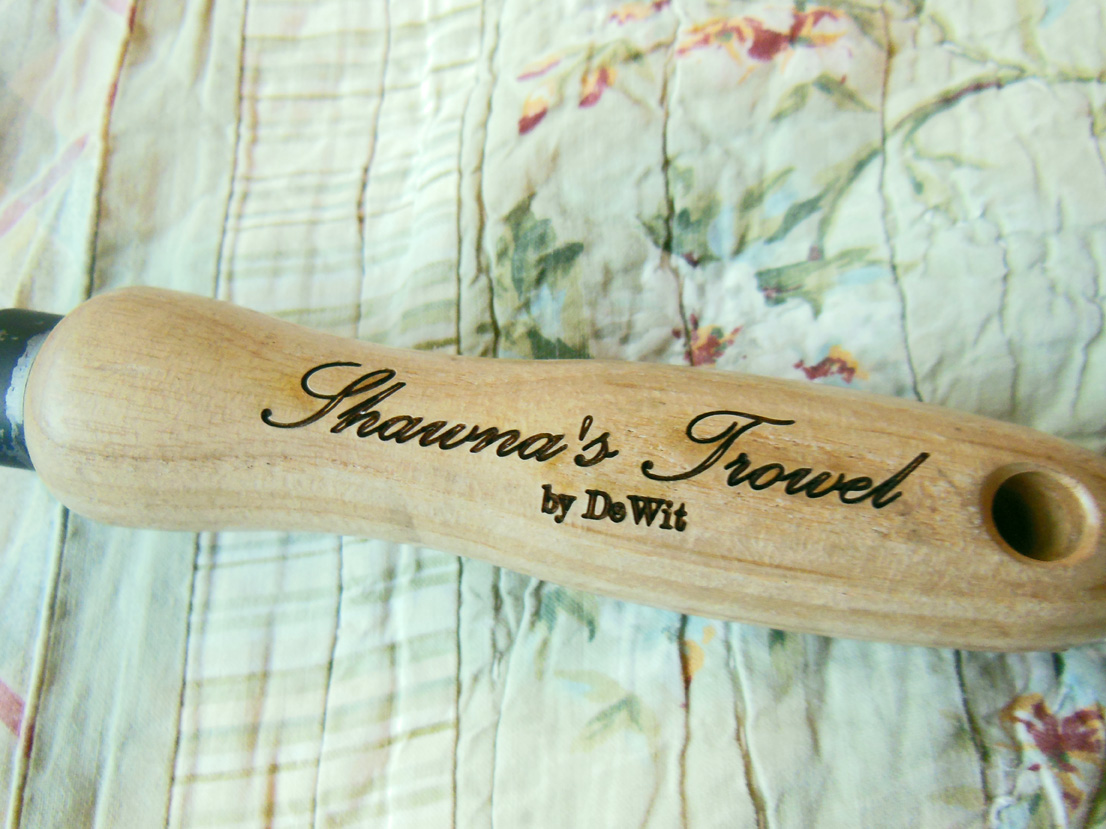

Back and forth the trowel goes from the hot forge to blacksmith to anvil for the many steps it takes to forge a garden tool. We reinforce the seam. A blacksmith shapes the handle (see above photos). Heat the tool again. Next we put it to a delicate hammer. Mold gently into shape. After more shaping, the blacksmith sharpens the end of the tool (below). The wooden portion of the handle is positioned and custom laser labeled (see bottom).

That’s the end of an absolutely wonderful tool building adventure. Making your own tool from scratch is amazing fun and learning how much care and love goes into every tool at the DeWit factory makes me appreciate using them and taking care of them all the more. I cannot wait to get out to the garden!

Special Note – The factory tour in the Netherlands and how to forge garden tools by hand was sponsored by DeWit Tools. All opinions are my own!

Hi Shawna,

Great to see your enthusiasm and passion into the profession of blacksmith. We can see you fully enjoyed your few hours at the productionsite of DeWit Garden Tools.

In Europe your Garden trowel is very popular and we are proud to have it in our webshop.

Especially for Christmas and the end of year gifts, it is a great gift to receive and to give away.

Thanks for your cooperation, to be followed…

Blacksmithing is FUN! I SO enjoyed having this adventure and can’t wait to see what happens next.

Plus the tool is cool – it functions very well as a potting soil bag cutter – love it!

Shawna

Shawna, that is The. Coolest. Thing. Ever. I almost cried when I saw that last photo with “Shawna’s Trowel” lasered onto it. The design of the tool is great. I’ve got one DeWit tool and I love it. I call it my “forky thing,” and I use it for a couple of different tasks. Cultivating the soil, for sure, but also to dig onions out when their roots want to hang on!

Thanks SO MUCH. I was SO SO excited and had the best time ever doing this. 🙂

::HUGS::

Shawna

I love this…perfect scoop to keep dirt in the scoop and that little cutter…perfection. Very cool Shawna!!

Works like a charm! 🙂